Inventory management decides what products to keep, how much to stock, and when to order, while warehouse management focuses on how those goods are stored, moved, and handled inside the facility.

Confusing the two can obscure digital strategy and hurt operations. Even with accurate forecasts, delays in picking, packing, or shipping can reduce service levels. The stakes are high as Gartner predicts over 75% of companies will use cyber-physical automation in supply chains by 2027.

Knowing where inventory management ends and warehouse management begins is vital. McKinsey research shows advanced inventory planning can cut stock by 20–30% while keeping products available.

However, these gains only happen if warehouses operate in sync with inventory, highlighting the importance of defining each function clearly in any supply chain digital transformation.

This article offers a thorough comparison of inventory vs. warehouse management, exploring their differences and overlaps to help businesses refine both.

What is inventory management?

Inventory management involves tracking and controlling a company’s materials, components, and finished goods to ensure the right items are available at the right time, without tying up too much capital. It covers forecasting demand, managing the procurement process, monitoring stock levels, and syncing with production or distribution schedules.

For example, Siemens rolled out a smart inventory system across its manufacturing plants to track components in real time. This cut production delays, reduced excess stock, and helped teams react faster to demand changes.

Strong inventory management gives businesses the clarity and control to keep operations running smoothly and make confident choices about growth and resource allocation.

What is warehouse management?

Warehouse management involves the storage, movement, and handling of goods within a facility to ensure efficient operations.

It covers the full journey inside the warehouse, from receiving shipments and organizing stock to tracking locations, picking orders, packing, and shipping. While inventory management decides what should be in stock, warehouse management ensures those items are easy to find and are removed from the warehouse on time.

For example, Cisco rolled out an IoT warehouse management system in its global distribution centres to improve pick-and-pack efficiency. The result: faster handling, higher order accuracy, and better visibility of stock movements, enabling tight deadlines to be met without unnecessary overstocking.

What is the difference between inventory and warehouse management?

Inventory and warehouse management are often confused, but they play different roles. Inventory management focuses on what to stock and when, while warehouse management handles how those items are stored, transferred, and delivered.

Let’s take a look at the differences between the two:

Inventory management

Inventory management is different from warehouse management in that it focuses on planning and deciding what to stock, how much to hold, and when to reorder. Its main goal is to balance supply with demand and control costs, without handling or moving products physically.

Warehouse management

Unlike inventory management, warehouse management deals with the practical handling of stock. It covers receiving, storing, organizing, and shipping items to keep operations efficient and accurate. The focus is on executing plans effectively, ensuring products move without deciding what or how much to stock.

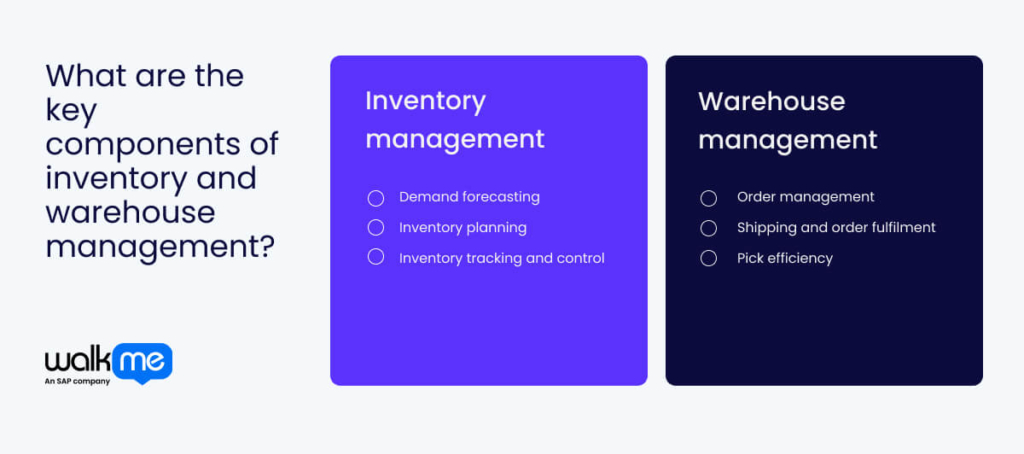

What are the key components of inventory and warehouse management?

Understanding the key components of inventory and warehouse management will give you a clear view of how each function supports operational effectiveness. It also ensures products are available and handled throughout the management of the supply chain.

Inventory management

Let’s take a closer look at the key components of inventory management:

Demand forecasting

Demand forecasting predicts what products customers will need based on past sales, trends, and behaviour. Good forecasting helps businesses avoid running out of stock or holding too much, keeps cash flowing efficiently, and allows teams to make smarter, proactive decisions about future supply needs.

Inventory planning

Inventory planning decides how much stock to keep, when to reorder, and which items are most important. It balances cost, storage space, and service levels. Clear planning enables businesses to become customer-centric without tying up unnecessary resources, thereby guiding procurement, production, and operations.

Inventory tracking and control

Inventory tracking and control keep an up-to-date view of stock levels and locations. It alleviates errors, prevents losses, and maintains accuracy. This visibility helps teams act quickly, follow plans reliably, and make informed decisions across the supply chain.

Warehouse management

Let’s take a closer look at the key components of warehouse management:

Order management

Order management keeps track of all incoming and outgoing orders, making sure nothing is missed or delayed. It sets priorities, monitors progress, and connects with inventory systems so teams know exactly what needs attention. Clear order management reduces mistakes and helps the warehouse run reliably for everyone involved.

Shipping and order fulfilment

Shipping and order fulfilment handle getting products from the warehouse to the right place at the right time. This includes careful packing, labelling, and arranging transport. Efficient fulfilment keeps operations predictable, avoids costly delays, and ensures that customers, partners, and colleagues all receive what they need on schedule.

Pick efficiency

Pick efficiency ensures items are retrieved quickly and accurately. Using smart paths, grouping orders, and using the right digital tools helps teams work faster and with fewer mistakes. High pick efficiency keeps operations tight, reduces stress on staff, and ensures products move through the warehouse in good time.

What are the different types of inventory management and warehouse management?

There are several approaches to managing inventory and warehouse operations, each designed to meet different business needs. Understanding these types helps organisations choose the right strategies and systems to keep stock accurate, digital workflows efficient, and operations running smoothly.

Inventory management

Let’s take a closer look at the different types of inventory management:

Fixed Order Quantity (FOQ) system

The FOQ system triggers a new order whenever stock drops to a set level. Companies order a consistent quantity each time, making budgeting and planning predictable. This approach works well for fast-moving products, ensuring replenishment happens on time without constant monitoring.

Fixed Time Period (FTP) system

The FTP system checks inventory at set intervals, like weekly or monthly. During each review, stock is topped up to a target level. This approach suits predictable or seasonal products, simplifies planning, and avoids constant tracking, though stock levels can fluctuate between reviews.

Continuous Review system

A continuous review system monitors stock levels in real time. Orders are placed immediately when inventory hits a set threshold. This method reduces shortages, ensures critical items are always available, and keeps capital tied up only when necessary.

Reorder Point system

The ROP system sets a specific inventory level that triggers an automatic reorder. It accounts for demand changes and lead times, helping businesses maintain essential stock without overstocking or scrambling for emergency replenishment.

Just-In-Time (JIT) system

The JIT system keeps inventory to a minimum, receiving goods only when needed. This reduces storage costs and waste while speeding up response to demand. JIT works best with reliable suppliers and well-coordinated operations.

Warehouse management

Let’s take a closer look at the different types of warehouse management:

Manual systems

Manual systems use paper, spreadsheets, and staff knowledge to track stock. They are simple and cheap but prone to mistakes and slow updates. Small warehouses can manage with this method, but it becomes difficult to keep up as operations grow or orders become more complex.

Basic computerized systems

Basic computerized systems record stock digitally but still need manual data entry. They improve organisation and reporting compared with paper methods, though mistakes can happen if data isn’t entered correctly. These systems suit mid-sized warehouses looking for better visibility without full automation.

Automated storage and retrieval systems (ASRS)

ASRS relies on machines to automatically store and retrieve items. It speeds up processes, reduces errors, and lowers labour costs. This approach works best in high-volume warehouses where accuracy and speed are critical.

Cross-docking systems

Cross-docking moves goods straight from incoming shipments to outgoing transport with little or no storage. It cuts handling time and storage costs, speeds up delivery, and is ideal for fast-moving products that need precise timing and coordination.

Mobile warehouse management systems

Mobile systems use handheld devices or tablets to manage inventory in real time. Staff can scan items, update locations, and track stock on the go. This approach increases flexibility and supports fast-moving warehouse operations.

Inventory management vs. warehouse management tools

Inventory and warehouse management rely on different types of tools to keep operations running.

Comparing these tools helps businesses understand which systems support planning, which streamline execution, and how each contributes to overall efficiency and accuracy.

Inventory management tools

Let’s take a closer look at inventory management tools:

AP Business One

SAP Business One brings inventory, sales, purchasing, and finance into one system. Stock can be tracked in real time, and reorders can be automated to avoid running out or overstocking. Many companies value it for keeping both operations and finances organised without needing extra software or complex setups.

Oracle NetSuite

Oracle NetSuite is a cloud-based system that manages stock, orders, and multiple warehouse locations. Its forecasting tools help predict demand and prevent mistakes. Businesses choose it for its ability to grow with them and for providing one clear, central view of all inventory and operations.

Acumatica

Acumatica is a cloud ERP made for mid-sized businesses. It tracks stock, sends alerts automatically, and manages workflows. With mobile access and multi-warehouse support, it keeps operations flexible. Teams appreciate the design’s ease of use, which enables them to work faster without extra steps.

Warehouse management tools

Let’s take a closer look at warehouse management tools:

SAP Extended Warehouse Management (SAP EWM)

SAP EWM runs every stage of warehouse operations, from receiving goods to storing, picking, and shipping. Real-time tracking helps avoid delays or lost items. It works especially well for large or complex operations that need a clear view of every product at all times.

Microsoft Dynamics 365 Supply Chain Management

Microsoft Dynamics 365 gives a cloud-based view of stock and warehouse workflows. Automatic alerts and predictive analytics help plan tasks, manage orders, and spot issues early. Its scalability makes it ideal for coordinating staff and processes across several locations.

Blue Yonder Warehouse Management

Blue Yonder uses real-time tracking and intelligent automation (IA) to make warehouses faster and more accurate. Advanced picking methods, flexible workflows, and smart predictions help reduce mistakes and speed up deliveries. It also provides precise stock data so teams can make quick, confident decisions.

What are the benefits of good inventory and warehouse management?

Strong inventory and warehouse management create a foundation for reliable and responsive operations. It helps businesses anticipate challenges and make smarter decisions, ensuring teams can act confidently even as demands and conditions change.

Inventory management

Let’s take a closer look at the benefits of good inventory management:

Accurate demand forecasting across multiple regions

Good forecasting helps businesses determine the optimal stock levels for each location. It stops shortages and too much inventory, making sure products are where they need to be. Teams can plan better, act faster when things change, and keep customers happy without confusion or wasted time.

Lower carrying costs through optimized stock levels

Keeping only the stock you need reduces storage costs, prevents waste, and frees cash for other uses. Businesses can meet customer needs without overbuying, keep operations oiled, and avoid cluttered warehouses, making daily operations easier and more efficient for everyone.

Warehouse management

Let’s take a closer look at the benefits of good warehouse management:

Faster fulfillment through automated workflows

Clear warehouse processes help orders move quickly from storage to shipment. Automation guides staff through tasks, reducing delays and keeping deliveries on time. Teams can work efficiently, focus on priorities, and handle more orders without stress, helping businesses meet customer expectations.

Improved order accuracy at scale

Good warehouse practices make sure the right products go to the right customers. Tracking stock and following simple, structured steps reduces mistakes, even with high volumes. This enhances customer care, lowers returns, and allows warehouses to grow and manage more orders without slowing down or creating extra problems.

What are some common challenges of inventory and warehouse management?

Inventory and warehouse management can be complicated, and even small mistakes can disrupt operations. Understanding common challenges helps businesses spot risks early and find ways to keep stock and workflows running smoothly.

Inventory management

Let’s take a look at some common challenges of inventory management:

Responding to real-time demand changes

In fast-moving markets, customer demand can shift without warning, and stock levels must adapt quickly. Teams need clear, real-time information to adjust orders effectively. Quick action prevents shortages or excess inventory and keeps operations steady.

Avoiding overstock while ensuring accuracy

Finding the right inventory balance is a constant challenge. Having too much stock ties up money and space, while having too little risks missing orders. Simple tracking, regular checks, and accurate records help businesses maintain the correct levels and run daily operations without complications.

Warehouse management

Let’s take a look at some common challenges of warehouse management:

Maintaining efficiency with warehouse staff

Warehouse teams often work under heavy pressure, with tight deadlines and high volumes, making digital efficiency essential. Digital tools can help, but they only work well when paired with clear instructions, organised workflows, and fair task distribution. When staff are supported, employee performance levels up, operations run smoothly, and orders get out on time, even during busy seasons.

Implementing warehouse management software

Introducing new software can disrupt warehouse routines if not managed carefully. Staff require software adoption, workflows may need adjustment, and systems must integrate. Gradual adoption, thorough training, and clear communication help teams use software inventory confidently, improving accuracy, speed, and overall business resilience.

How to integrate inventory management and warehouse systems?

Integrating inventory and warehouse systems means making sure stock data and warehouse actions work together.

The goal is always to know what’s in stock, where it is, and when it will be needed. Using software that updates inventory levels, orders, and warehouse movements in real-time helps teams stay on top of everything and prevents mistakes.

Processes must also match, which means inventory decisions, like what to restock or move, should guide warehouse tasks such as picking, packing, and shipping. At the same time, warehouse updates should automatically adjust inventory records so data is always accurate.

Cloud-native platforms or system integration tools can connect new and legacy systems without replacing everything. Training staff to understand how inventory and warehouse actions link ensures the right decisions are made.

Remember, proper integration eases delays, reduces errors, and helps businesses respond quickly to changing demand across locations.

Comparing inventory management and warehouse management

Understanding the difference between inventory management and warehouse management directly shapes how products are designed, pushed, and delivered.

Inventory management sets the agenda, deciding what to stock and when, while warehouse management puts that plan into action, ensuring goods are stored, handled, and shipped efficiently.

When both roles are clearly defined and supported by modern tools, businesses avoid costly mistakes and respond faster to changes. And when these functions work in sync, companies gain better visibility, control, and flexibility, making it easier to scale without wasting resources.

Fast-changing demand and large-scale digital transformation necessitate mastering both disciplines to run efficient, reliable, and resilient supply chains that deliver real business value.

FAQs

These systems show the stock’s location in real time. Teams can track shipments, coordinate warehouses, and make sure the right products reach the right place on time. This visibility helps businesses react quickly to delays and keep customers satisfied worldwide.

AI predicts what products will be needed and when. It can suggest the fastest picking routes, flag low stock, and spot inefficiencies. Giving teams clear guidance, AI reduces errors, minimizes excess inventory, and accelerates fulfillment without relying on constant manual checks.

ROI comes from fewer stockouts, lower storage costs, faster fulfilment, and fewer mistakes. Tracking these improvements before and after system integration shows how much time and money businesses save while keeping operations scalable.