Supply chains are under more pressure than ever. Customers expect faster, more reliable deliveries, yet many logistics companies still rely on outdated systems that limit visibility and efficiency.

Without real-time tracking, accurate delivery estimates are challenging—and resource shortages, ranging from drivers to vehicles, exacerbate the problem. The result? Higher costs, missed deadlines, and strained customer relationships.

This is where digital transformation in logistics becomes essential. By adopting technologies such as IoT sensors, AI-driven forecasting, and cloud-based platforms, logistics teams can enhance visibility, streamline operations, and make informed decisions in real-time. Digital tools also enhance communication, reduce errors, and support better employee morale and retention by removing friction from daily workflows.

In this article, we’ll define what digital transformation means for logistics, explore the key technologies driving change, highlight benefits and challenges, and share real-world examples to help you build a more resilient supply chain.

What is digital transformation in logistics?

Digital transformation in logistics is the integration of technologies such as IoT, artificial intelligence (AI), automation, and cloud computing to optimize supply chain operations. It enables real-time visibility, predictive insights, and greater efficiency across the logistics network.

For example, IoT sensors on trucks and shipments provide live updates on location and condition, while warehouse robots and drones automate repetitive tasks to accelerate fulfillment. AI-powered tools optimize delivery routes, predict potential delays, and help leaders make data-driven decisions. Cloud platforms then ensure that information is shared seamlessly across teams and partners.

The result is faster, more reliable delivery performance, reduced costs, and greater resilience. Digital transformation also enhances employee workflows, supports sustainability goals, and equips businesses to adapt quickly to changing customer demands and market conditions.

What are the technologies that drive digital transformation in logistics?

Digital transformation in logistics depends on a set of core technologies that enhance visibility, automation, and decision-making. Together, these tools help organizations modernize supply chains, improve resilience, and deliver a better customer experience.

Cloud computing

Cloud platforms centralize applications and data, enabling real-time collaboration across global supply chains. They provide scalability to handle demand fluctuations, reduce IT overhead, and allow logistics companies to integrate partners and third-party systems seamlessly.

Internet of Things (IoT)

IoT sensors track shipments, vehicles, and inventory in real time. This constant flow of data improves visibility, reduces losses, and enables predictive maintenance. For logistics providers, IoT transforms operations from reactive to proactive, ensuring faster and more reliable deliveries.

Robotics

Automation tools such as warehouse robots and drones streamline repetitive tasks, from picking and packing to last-mile delivery. Connected to central systems, these robots reduce errors, increase throughput, and improve workplace safety while lowering operational costs.

AI

Artificial Intelligence (AI) drives intelligent decision-making. It analyzes supply chain data to optimize delivery routes, forecast demand, and predict delays before they occur. AI also supports automated workflows, freeing employees from manual tasks and enabling them to focus on higher-value activities.

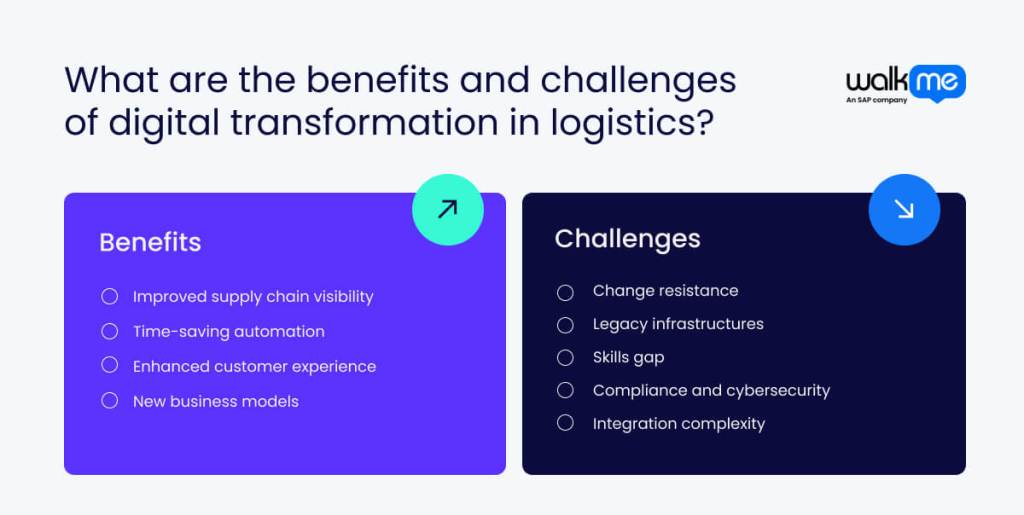

What are the benefits of digital transformation in logistics?

Digital transformation in logistics equips companies with tools such as AI, IoT, and cloud platforms, enabling them to modernize operations, reduce costs, and strengthen customer relationships. By applying these technologies strategically, logistics leaders can achieve both short-term efficiency and long-term resilience.

Improved supply chain visibility

Real-time tracking through IoT and cloud-based platforms provides end-to-end transparency. Companies can anticipate disruptions, optimize inventory, and share accurate delivery updates with customers, thereby strengthening trust and improving service reliability.

Time-saving automation

Automation through robotics and intelligent software reduces manual workloads, including order processing, inventory management, and scheduling. This not only increases accuracy but also frees employees to focus on higher-value tasks, improving morale and retention.

Enhanced customer experience

With digital tools like AI-powered tracking and proactive notifications, customers gain reliable insights into shipment status. Faster response times and consistent communication improve satisfaction and loyalty.

New business models

Digital transformation opens the door to innovation beyond traditional freight. Logistics providers can offer on-demand delivery, subscription-based services, and customized supply chain solutions, unlocking new revenue streams and a competitive advantage.

What are the challenges of digital transformation in logistics?

Digital transformation in logistics presents significant benefits, but it also poses substantial challenges. Companies that underestimate these challenges risk stalled initiatives, wasted investment, and a competitive disadvantage.

Change resistance

Change resistance occurs when employees are hesitant to adopt new digital tools. This is often due to fear of job loss or discomfort with unfamiliar systems. This human barrier can slow progress, making communication and employee training essential for a successful transition to new technologies.

Legacy infrastructures

Older Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and ERPs are difficult to integrate with modern digital platforms. These silos limit visibility, increase costs, and block innovation. Replacing or modernizing legacy infrastructures is often one of the toughest steps in transformation.

Skills gap

Technologies like AI, robotics, and IoT require new expertise. Upskilling and reskilling the workforce is essential, but it can be costly and time-intensive. Without this investment, adoption stalls and ROI diminishes.

Compliance and cybersecurity

Logistics firms manage sensitive customer, financial, and partner data. Meeting strict data privacy regulations (e.g., GDPR, CCPA) and defending against cyberattacks is critical to maintaining trust and avoiding penalties.

Integration complexity

Finally, supply chains involve multiple partners and systems. Ensuring interoperability across carriers, warehouses, and vendors adds complexity that must be addressed early.

What are some examples of digital transformation in logistics?

Real-world examples can demonstrate to companies how to initiate a digital transformation and update their legacy applications. Here are some examples of digital transformation in logistics to help with your implementation:

Predictive analytics and demand planning

Predictive analytics uses past information to guess what will happen next. It helps companies forecast what customers will want and spot potential problems in the supply chain before they occur. Demand planning is the process of using these forecasts to decide how much product to have on hand.

When you combine these two, it changes everything. Instead of reacting to problems as they happen, companies can prepare for them in advance. This shifts their logistics from being a manual, reactive process to one that’s driven by data.

Repsol is doing exactly this through AI agents that automate complex tasks, such as inventory tracking and supply chain forecasting. This frees up employees to focus on more important work.

This tool also provides data-driven insights, enabling the company to quickly solve problems, reduce delays, and make informed decisions. This enhances Repsol’s entire logistics network, making it stronger and more reliable.

Warehouse automation

Warehouse automation involves the use of robots and software to automate tasks. This includes finding items, packing boxes, and sorting them for shipping.

This represents a significant shift in how companies manage their products. Robots do the physical work, while artificial intelligence acts as the brain, predicting what people will buy and managing inventory. Everything is interconnected, enabling the system to function smoothly.

Flexe, a logistics company, does this by helping restock physical warehouses and stores automatically using Flexe nodes. With options like BOPIS (Buy Online, Pick Up In-Store) gaining popularity, products are moving through stores faster and need to be restocked more frequently. Through this technology, logistics companies can benefit from faster deliveries and quicker restocking.

Digital twins

Digital twins can create virtual, real-time models of physical assets, processes, or entire supply chains. IoT sensors can collect data, including location, temperature, and inventory levels. They feed it into the digital twin to reflect real-world conditions and predict future issues.

The real power of digital twin technology is that you can experiment with it. You can test out new ideas, including a different warehouse layout or a new delivery route, in this virtual world first. This technology also enables companies to track shipments accurately and prepare for potential delays.

For example, ZeroNorth helps shipping companies become more efficient and use less fuel. Their AI technology creates a digital twin of a ship to predict its fuel needs in any situation. ZeroNorth also provides tools to improve the performance of key ship parts and plan the safest and most profitable routes.

Cloud computing

Think of cloud computing as using the internet to run your business instead of buying and managing your own expensive computer servers. Companies can rent the computing power they need, which is much cheaper and more flexible.

An S&P Global survey found that 40% of shipping and logistics firms see cloud computing as the most critical technology for their digital transformation. For logistics, this creates a central online place where everyone involved in the supply chain can see and share the same up-to-date information.

This makes it easy to connect different tools and automate simple, repetitive tasks. It also makes it easier to add other new technologies, including AI and smart sensors, without a lot of hassle. Managers can see the big picture clearly and make decisions based on real data.

Last-mile delivery technology

Getting a package from a local warehouse to your front door is the most challenging and expensive part of its journey. This is known as the last mile, and new technology is changing it.

This type of tool can provide you with live tracking on a map when you’re waiting for a food delivery. It also plans the fastest routes for drivers, saving time and fuel. This gives you, the customer, more control and a clear idea of when your package will arrive.

Blockchain

Blockchain acts as a shared digital notebook for tracking products as they move from the factory to the store. Everyone involved in the supply chain can track the location of a product at any time.

Once information is added to the notebook, it’s locked in and can’t be changed or deleted. This makes the system very secure and builds trust between partners.

Blockchain also offers smart contracts, which are like automatic checklists. For example, a payment can be sent to a supplier automatically as soon as a shipment arrives. This speeds things up and reduces human error.

Drone delivery

Drone delivery is changing logistics by replacing traditional delivery methods with technology-driven systems. These drones use AI to navigate their way to your doorstep. Because they fly, they avoid getting stuck in traffic, which means they can deliver items much faster. This is ideal for urgent items you need immediately.

While setting up a drone delivery system is initially expensive, it can save companies a significant amount of money over time. It costs less to send a drone than to pay for a driver and a truck for each delivery.

Walmart puts this into practice by using drones to offer fast deliveries and meet the growing demand for orders in 30 minutes or less. Their drones can carry 5 to 10 pounds of goods, covering a significant share of deliveries.

Drone delivery is also more eco-friendly, as it reduces road traffic and lowers environmental impact. Since launching in 2021, Walmart has delivered over 120,000 packages by drone and plans to expand its operations further.

Apply digital transformation in logistics for a more agile organization

Adopting new technology within logistics enables companies to operate faster and more flexibly. This digital move improves transparency and keeps customers happy with real-time updates and faster service. Successful implementation requires a clear plan, the right technology, and well-trained employees.

This evolution builds a more resilient business, utilizing data to anticipate disruptions such as adverse weather and proactively reroute shipments. It helps meet rising customer expectations for speed and accuracy while improving innovation, such as offering greener shipping options.

By leveraging logistics as a strategic advantage, companies can secure a strong competitive edge in a demanding market, ensuring they are well-prepared for future opportunities.

FAQs

Digital transformation is crucial in logistics because it enhances supply chain visibility through real-time tracking and reduces costs through automation. It also enhances customer experience with faster delivery and regular updates, while making supply chains more flexible to handle disruptions. This helps companies stay ahead of the competition.

To implement digital transformation in logistics, review your current operations and plan with the support of leadership. Utilize tools like IoT sensors, AI, and cloud platforms to enhance route planning. Train employees to utilize digital tools and collaborate with partners to enhance your strategy.